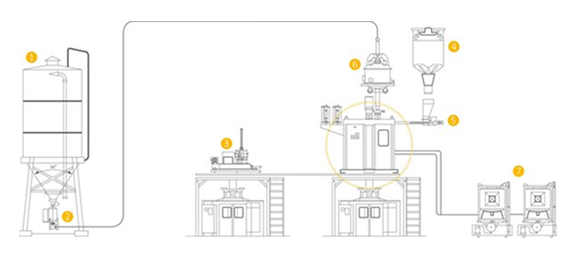

Complete sand preparation systems

In addition to individual mixers, Laempe's range includes auxiliary components and complete systems to meet the specific requirements of sand preparation for different core processes.

1. Sand silo

The right silo for your requirements: Factory-welded, mobile, with a filling pipe, withsupport structure, pressure relief vent, or with a feed hopper for additives. Pneumatic filling can take place using a pamper truck or stationary systems. Dust collection, overfill protection, and fill level measurement technology ensure transparency and safety.

2. Sand sender and sand sender line

The sand transporter ensures that the bulk material is blown through a pipe to its destination. The transporter is loaded with sand, sealed, and pressurized, blowingsand through the pipe to its destination.

3. Sand transportation

There are various technical options available for transporting the sand:

- Sand conveyor belt for supplying multiple machines

- Suspended transport hopper with double undercut gates on a monorail

- Sand transport hopper with double undercut gates on rails, characterised by its low installation height

- Sand transport trolley on rails, self-cleaning. This solution is recommended if different recipes are used

4. Big bags or day bin

One- or two-cell bins (heated/unheated) or big bags can be used to store the sand/additive.

5. Additive supply

The additive supply system is attached to the mixer in a modular fashion and is filled from big bags or sacks. The additive is supplied to the mixer via a feed screw. The control unit can be used to set the volume or weight as required.

6. Heater /cooler / classifier

Sand heater/cooler/classifier can be used to keep the sand temperature constant in order to optimise core quality. In addition, dust is removed, which minimises binder consumption and improves gas throughput.

7. Binder supply

The binder supply system comprises various components that can be pieced together in a modular fashion: from a simple suction lance which comes straight out of the binder drum to a central supply for multiple mixers. The central binder supply system consists of the following components:

- Central container/drum storage with buffer tank and pump system

- Intermediate tanks (heated/unheated)

- Pipe system (heated/unheated)

- Control unit with display (separate or integrated)